Reflecting the Universe: building the world’s largest telescopes Understand article

For hundreds of years, telescopes have helped astronomers unravel the mysteries of the Universe. But what’s involved in making – and maintaining – the complex instruments of today?

In 1608, a German-Dutch spectacle maker named Hans Lippershey filed a patent for a small device that used lenses to focus light and produce a magnified view of distant objects: it was the earliest known design for a telescope. Shortly after this invention, Galileo famously built one of his own, and was the first to use a telescope for astronomical observations. Four hundred years later, telescopes are still vital for astronomy, but they have evolved from small, hand-held instruments to gigantic, computer-controlled devices.

Today, most of the world’s largest optical and infrared telescopes – many of which are built and operated by the European Southern Observatoryw1 (ESO) – use mirrors rather than lenses to gather and focus light. The larger the mirror, the more light can be collected, allowing astronomers to see fainter celestial objects – which are often further away – in greater detail. Although large mirrors are easier to produce than large lenses, producing modern astronomical telescopes is still a real challenge.

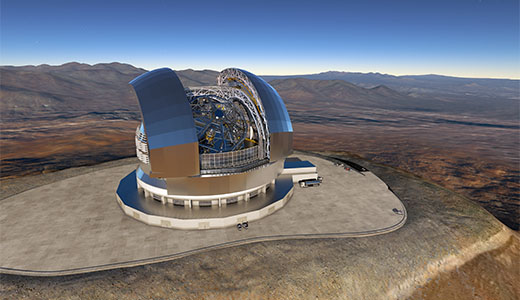

ESO/L Calçada/ACe Consortium

From Newton to today

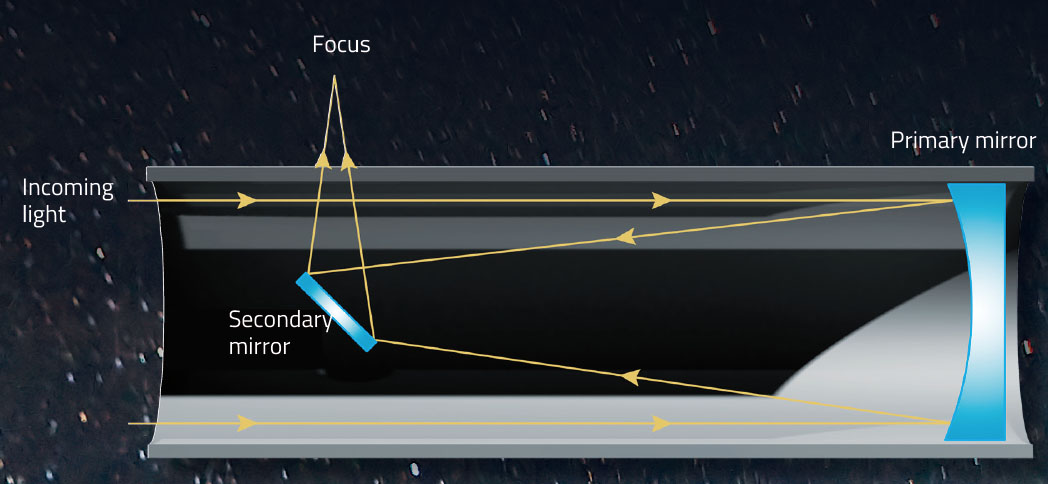

The first successful reflecting telescope (one that uses mirrors rather than lenses to focus light) was built by Sir Isaac Newton in 1668. The basic Newtonian design uses a concave primary mirror (the first mirror that starlight hits on entering the telescope) and a flat secondary mirror, which is positioned above the primary mirror and angled diagonally to reflect and direct the light to an eyepiece. The same principle is used today in many amateur and professional telescopes. In modern telescopes, mirrors allow the light to be directed to different cameras or detectors in place of the eyepiece, and they also enable telescope designs to be more compact.

Newton’s first reflector telescope used a primary mirror measuring 3.3 cm in diameter. Now, the biggest single reflecting telescope mirrors in the world are approximately 8 m in diameter. ESO’s Very Large Telescope (VLT) in Chile, South America, for example, consists of four telescopes each with a primary mirror diameter of 8.2 m.

ESO/N Bartmann

Making the mirrors

The material of choice for most professional telescope mirrors is glass (such as borosilicate glass, used for ‘Pyrex’ cookware) or a special glass-ceramic composite material. Such materials can be ground and polished to exactly the right shape to produce a good image. They also don’t change shape or size in response to temperature fluctuations. This is especially important because many telescopes are located high up on mountains or in the desert, where temperatures vary significantly between day and night.

To focus as much of the faint starlight as possible, the surface of primary mirrors must be highly reflective. The reflectivity is created using an extremely thin coating of a light-reflecting material, the identity of which depends on the operating wavelength of the telescope. For example, silver or aluminium is often used on optical and near-infrared telescope mirrors.

Bigger and better

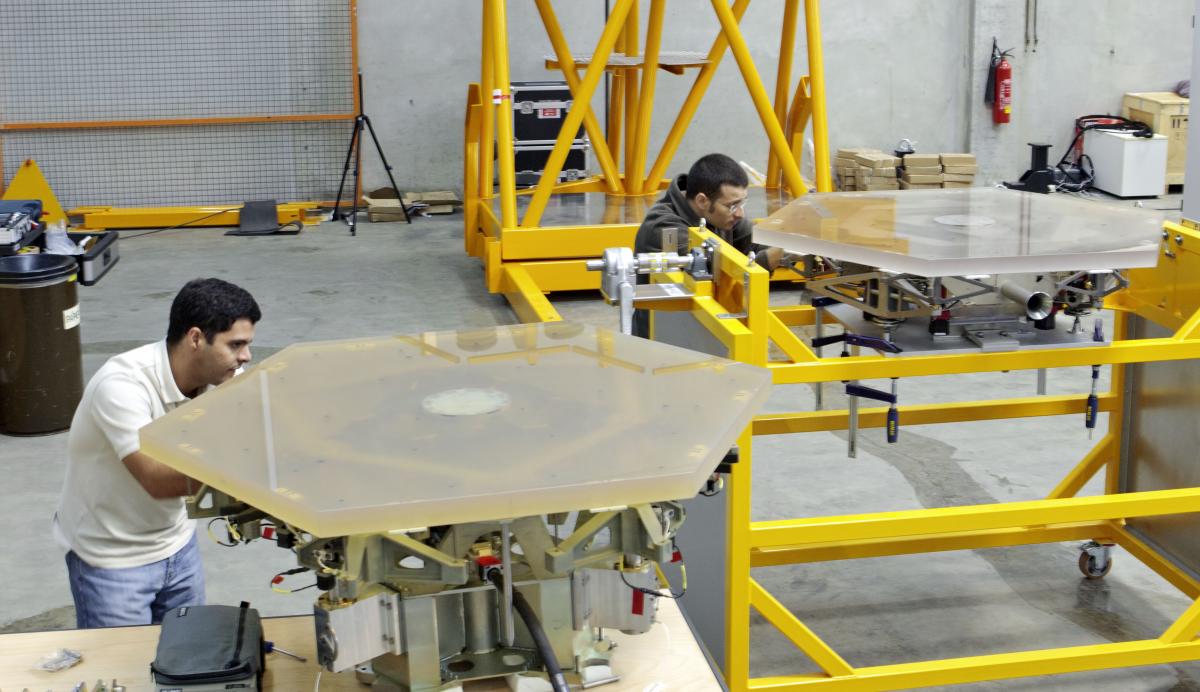

The size of telescope mirrors has increased considerably in the past 50 years, but astronomers always want to go bigger. There is still a limit, however: a mirror much larger than 8 m would be incredibly difficult to grind and polish. So, one solution is to build segmented mirrors instead. These consist of individual, often hexagonal, sections that together make up one huge light-collecting area.

Currently, the world’s largest segmented mirror – the Great Canary Telescope, in the Canary Islands, Spain – measures 10.4 m across and comprises 36 segments. But in 2024, it will be superseded by the Extremely Large Telescope (ELT), which is under construction in the Atacama Desert in Chile. The primary mirror, measuring 39 m in diameter, will be made up of 798 segments, each with an area of around 1.4 m2. This huge telescope, which will be operated by ESO, will observe the Universe at optical and near-infrared wavelengths.

Further telescopes that are also underway, such as the Thirty Meter Telescope in Hawaii, have adopted a similar approach, using a large number of small segments. Others, such as the Giant Magellan Telescope in Chile, will comprise fewer – but larger – segments.

ESO

A smooth surface

To produce sharp images and accurate measurements, the surface of the mirrors must be perfectly smooth. For the ELT, each individual segment will be polished to an accuracy of within 15 nanometres. This means that if one segment were the size of Europe, any remaining bumps on the surface would be the size of a ladybird.

As mirrors (single or segmented) get bigger, they start to sag under their own weight due to the effects of gravity, thereby reducing their evenness. To compensate, the VLT relies on a technique called active optics, which uses 150 actuators to adjust the mirror, making corrections roughly every 30 seconds. For the ELT, it’s not just that the individual segments need to be extremely smooth: the segments must also be perfectly aligned with their neighbours to achieve the same effect as a single mirror. The ELT will have a total of 4524 sensors on the edges of the mirror segments; these will constantly report on their positions, allowing each segment to be precisely adjusted using 2394 actuators. This active optics system will make the overall surface of the primary mirror smooth to the accuracy of within about 50 nanometres – a thousandth of the thickness of a human hair.

ESO

Maintaining reflectivity

To ensure that the surface of the mirrors remains as reflective as possible, they must be protected from dust in high winds. When dust accumulates on the mirrors, it may reduce the reflectivity by only a few per cent, but every photon is valuable for producing high-quality images. Dust also scatters light and reduces the contrast in the images. During the day, the mirrors are kept covered, and at night the telescope is tilted before the dome is opened, so that anything on the roof (such as dust or bird poo) doesn’t land on the surface of the mirrors.

Over time, the reflective coatings deteriorate, so the mirrors need to be recoated on a regular basis. The primary mirrors of the VLT, for example, must be transported down from the observing platform to the base camp roughly every 18 months to be recoated. It is particularly challenging to deal with the most expensive and delicate part of the telescope, so the mirror is transported at a speed of just 5 km/h. The whole process (from removal to replacement) takes around one week.

For the ELT primary mirror, each of the 798 segments will also need recoating every 18 months. The most efficient way to do this will be to remove, recoat and replace two or three segments every single day. The telescope can still operate efficiently with a couple of segments missing, allowing for maximum operation time. By contrast, when any of the VLT mirrors are being recoated, that telescope is out of service.

Exploring the Universe

Designing, building and operating such large-scale telescopes is no easy task. But the exciting prospects – discovering Earth-like planets, measuring the properties of the first stars and galaxies, and probing the nature of dark matter and energy – are worth the hard work. In the coming decades, the world’s most advanced telescopes have the potential to revolutionise our understanding of the Universe, much as Galileo’s telescope did 400 years ago.

Web References

- w1 – ESO is the foremost inter-governmental astronomy organisation in Europe and the world’s most productive ground-based astronomical observatory, with its headquarters in Garching, near Munich in Germany, and its telescopes in Chile.

Resources

- Learn more about the VLT and ELT on the ESO website.

- For an infographic comparing the size of the ELT main mirror with that of other major ground-based telescopes, visit the ESO website.

- Find out more about the mirror production for the ELT by visiting the SCHOTT website.

- Learn what it’s like to work at the VLT in the Atacama Desert in Chile. See:

- Pierce D (2006) Running one of the world’s largest telescopes. Science in School 1: 56–60.

- More information on the primary mirror of the ELT is available in ESO’s quarterly journal, The Messenger.

Institutions

Review

Reflection is a central concept of waves and optics topics in school science curricula. Teachers can draw on this article, which gives up-to-date information about mirrors in large modern telescopes, to bring such topics to life for students. Moreover, it can help to make students aware of the applications of science and the challenges that modern technology can overcome.

Comprehension questions could include:

- Who made the first astronomical observations using a telescope?

- Who built and used the first reflecting telescope?

- Why is glass used to make mirrors found in large astronomical telescopes?

- How it is possible to build telescopes with mirrors greater than 8 m in diameter?

Stuart Farmer, physics teacher, Robert Gordon’s College, Scotland, UK